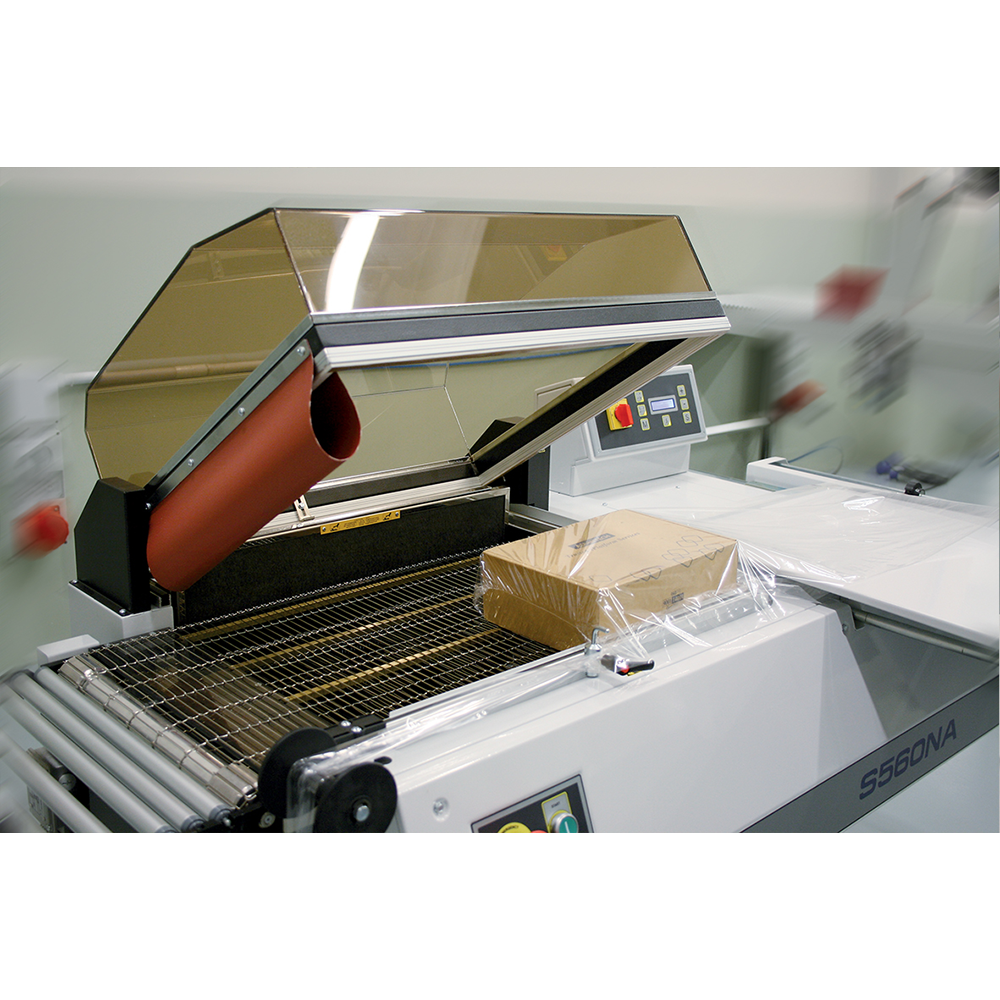

S560NA – L-Seal Automatic Hood Packer

$9,315.00

- Sealing bar: 22″ x 17″ Coated blade

- Up to 900 Packs/Hour

- Maximum product height: 10″

Considering Financing or Leasing?

Qualified applicants can get approved for financing in as little as seconds with CIT . Applying online is simple. Click the link below to start your application!

Please note that we are not affiliated with CIT Group Inc. and any finance related questions should be directed to their offices.

Additional information

| Brand | SMIPACK |

|---|---|

| Model | S560NA |

| Product Type | L-seal hood packer |

| Max Film Width | 24" |

| Max Tray / Product Height | 10" |

| Max Tray / Product Width | 16" |

| Optimal Throughput | 900 packs/hour |

| Max Tray / Product Length | 20" |

Features

- Sealing and shrinking in one operation only.

- PTFE coated sealing blade.

- Permanent liquid cooling system of the sealing bar

- Viewer of the coolant level

- Height adjustment of the packaging plate by an external outcrank

- Mobile product-holding plate, loose from the film reel support to allow a better adjustment of the film to the pack size

- Emergency button

- Flextron® control system equipped with 16 bit microprocessor for machine control and supervision and modular power section separated with solid state relays

- Backlighted multilanguage LCD panel

- Possibility of storing up to 6 different working cycles.

- Seal temperature controlled by microprocessor.

- Shrinking temperature and time controlled by microprocessor.

- Adjustment of the shrinking delay

- Automatic pack discharge by a motorized conveyor controlled by microprocessor.

- Automatic hood closing and re-opening

- Hood safety device.

- Available pack formation methods: a) sealing only; b) sealing and shrinking.

Options

- Scrap winder device. OPTIONAL

- Double reel support. OPTIONAL

- Stainless steel packaging plate. OPTIONAL

- Foot pedal kit to start the working cycle. OPTIONAL

Specifications

| Specification | Measurement | Comments |

|---|---|---|

| Power Supply | 220-240V; 1PH-N-PE; 50/60 Hz. | |

| Max Absorbed Power | 3750 W. | |

| Sealing Sizes | 22″ x 17″ | |

| Maximum Product Height | 10″ | |

| Production | Up to 900 Packs/Hour | |

| Maximum reel size | 11″ x 23″ | |

| Machine dimensions | 80″ x 32″ x 43″h. | |

| Recommended working temperature | FROM +47 °F TO +104 °F | |

| Advised Film Quality | · Material: PVC, polyolefin , micro-perforated film· Thickness: from 10 to 50 micron – from 42 to 100 gauge | |

| Warranty | 365 days for electrical, electronic and mechanical parts. | NOT INCLUDED: parts subject to normal wear and tear, and technicians labor, travel & lodging expenses. |